Industry Analysis: The Rise and Prospects of Spade-Type PTC Heaters in Household Appliances

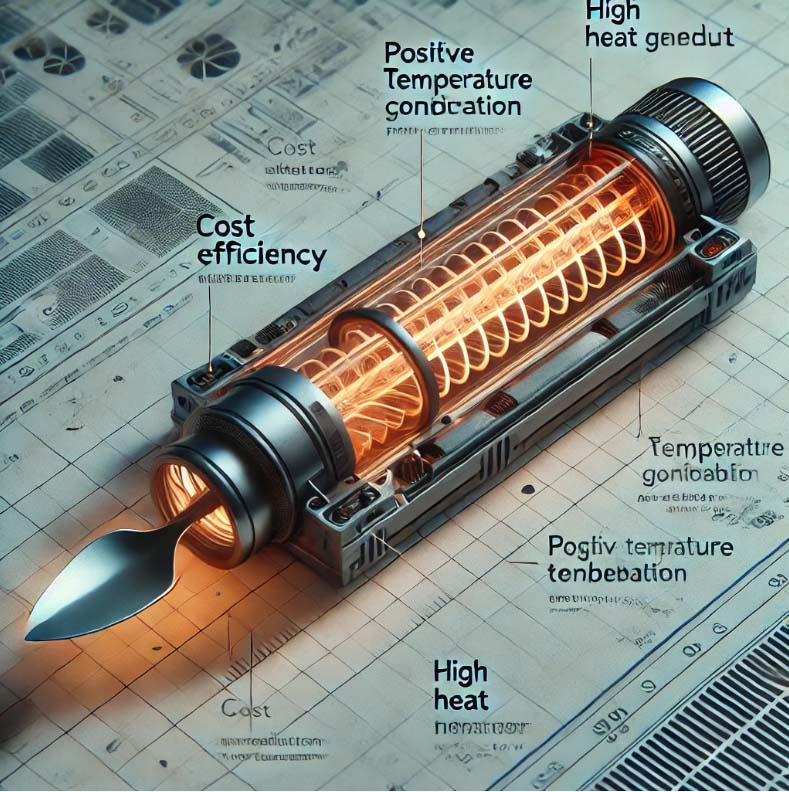

As household appliance technology continues to evolve, electric heaters play a pivotal role in devices like air conditioners and water heaters. In recent years, a new type of technology, the spade-type PTC (Positive Temperature Coefficient) heater, has gained prominence. With its significant cost advantages and higher heating efficiency, it is gradually replacing traditional adhesive-type PTC products. This trend reflects the industry’s dual pursuit of efficiency and cost-effectiveness and signals a new direction for technological development in the electric heater market.

I. Limitations of Traditional PTC Heaters

Adhesive-type PTC heaters were once the primary choice in the household appliance industry. Their core design involved bonding PTC components to heat dissipation plates using thermally conductive adhesives, converting electrical energy into heat. However, this traditional structure has notable shortcomings:

1.Higher Costs

The adhesives used are relatively expensive, and the manufacturing process requires multiple complex steps, increasing production costs.

2.Limited Heat Dissipation Efficiency

Thermal conductive adhesives cause energy loss during heat transfer, reducing overall efficiency.

3.Lower Reliability

Over time, adhesive layers may degrade or detach, leading to performance issues or even failure.

These drawbacks have limited the market adoption of adhesive-type PTC products and paved the way for new technologies to emerge.

II. Advantages of Spade-Type PTC Heaters

Compared to traditional adhesive-type products, spade-type PTC heaters feature an innovative design and process that address the above issues. Their key advantages include:

1.Lower Manufacturing Costs

Spade-type designs employ mechanical clamping, eliminating the need for costly adhesives and simplifying production. This cost-effective manufacturing approach aligns with the industry’s demand for high performance at low cost, enhancing companies' competitiveness.

2.Higher Heating Efficiency

By tightly coupling the PTC components directly to the heat dissipation plates, spade-type structures minimize heat transfer loss, improving overall efficiency. This characteristic is particularly valuable in high-power applications such as air conditioners and water heaters, ensuring faster and more even heating.

3.Greater Structural Stability

The mechanical clamping design provides higher long-term stability. Unlike adhesive layers, which can degrade, spade-type PTC heaters exhibit greater durability and a longer lifespan, reducing maintenance costs for end-users.

4.Environmentally Friendly

Without adhesives, spade-type PTC heaters align better with environmental protection standards, avoiding the potential pollution associated with industrial glues. This meets the growing global emphasis on green manufacturing.

III. Current Market Applications and Future Prospects

Spade-type PTC heaters are increasingly utilized in a wide range of household appliances, becoming a standard core component in air conditioners, water heaters, and dryers. In China's vast appliance market, the penetration rate of this technology is rising rapidly.

1.Air Conditioning

With the growing demand for efficient heating, particularly in colder regions, heating performance has become a key benchmark for air conditioners. Spade-type PTC heaters, with their efficient heating performance and stability, have become the preferred solution for electric heating systems in air conditioners.

2.Water Heaters

Water heaters demand high heating efficiency and durability. Spade-type PTC products provide stable thermal output in a short time while significantly reducing failure rates, making them increasingly popular in the water heater industry.

3.Future Development Potential

As smart appliances rise in popularity, the performance requirements for electric heaters will continue to grow. Spade-type PTC heaters, with their cost-effectiveness and efficiency, are well-positioned to meet future market needs and may even expand into broader fields such as automotive heating and industrial heating applications.

IV. Transformational Impact on the Industry Chain

The rise of spade-type PTC heaters not only reshapes the market landscape of the product itself but also drives changes across the entire industry chain. From upstream raw material suppliers to midstream manufacturers and downstream appliance producers, all stakeholders are adjusting and optimizing to accommodate this new technology.

- Upstream: The demand for high-quality PTC components and heat dissipation materials is increasing, prompting suppliers to enhance their technological capabilities.

- Midstream: Manufacturers are continuously refining spade-type processes and improving automation levels to scale up production.

- Downstream: Appliance manufacturers are redesigning products to fully leverage the advantages of spade-type PTC technology, developing more efficient and intelligent appliances.

The emergence of spade-type PTC heaters is the result of technological innovation and market demand. With their advantages of low cost, high efficiency, and high reliability, they are gradually replacing traditional adhesive-type products and becoming a new favorite in the household appliance industry. In the future, this technology is expected to further drive innovation in the electric heating field, creating more opportunities for related enterprises. In today’s competitive era, only continuous innovation can ensure a place at the forefront. The success of spade-type PTC heaters exemplifies this principle perfectly.