ZH-450: The Preferred Solution for Automated Assembly of Heating Elements

As the electric heating equipment industry continues to evolve, the need to reduce labor costs, increase production efficiency, and ensure product quality has become a primary concern for many companies. The ZH-450 multifunctional machine, developed by Guangdong Zhenghe Intelligent Technology Co., Ltd., stands out with its exceptional automation and intelligent features, making it an ideal choice for heating element production companies. This equipment integrates automatic assembly, welding, and resistance testing, allowing enterprises to achieve a high level of automation, significantly improving production efficiency and product quality, and providing a comprehensive solution for electric heating element production.

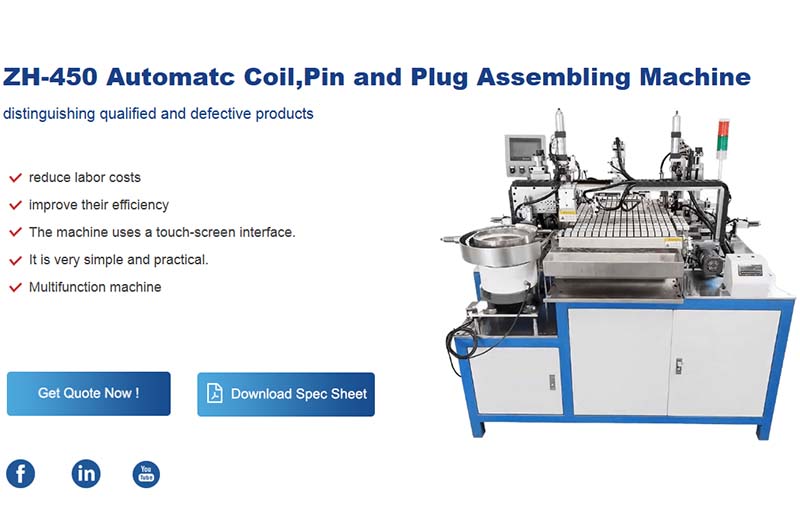

1. Automated Assembly Functions of ZH-450

The ZH-450 multifunctional machine is specifically designed for the automatic assembly of coils, pins, and plugs. Innovatively combining the assembly of upper and lower pins with coils, lower plug installation, and resistance value testing, the machine completes the entire process with high efficiency. Through precision-controlled robotic arms and sensors, the ZH-450 ensures the accurate assembly of upper and lower pins, coils, and plugs, minimizing the need for manual intervention. Additionally, the ZH-450 employs an advanced touch-screen interface, which is simple and intuitive to operate. Users can easily set and adjust the assembly process with a few touches on the screen. Compared to traditional manual assembly, this automated design not only enhances production efficiency but also improves the consistency and reliability of the products.

2. Integrated Welding and Resistance Testing

The ZH-450 can not only assemble coils and pins but also automatically weld the terminal pins to the coil and conduct resistance testing on the assembled parts. This feature is crucial in the heating element manufacturing industry, as resistance value is a key indicator of heating element performance, directly impacting product safety and longevity. The ZH-450, with its integrated resistance testing module, can detect the resistance value of each product in real-time, automatically distinguishing qualified from defective products to ensure quality before dispatch. Moreover, during the manufacturing of 20,000 units, the electrode tip does not require grinding, significantly reducing maintenance costs and production downtime, thus improving continuous production and equipment durability.

3. Reducing Labor Costs and Increasing Production Efficiency

The ZH-450 by Zhenghe Machinery significantly reduces labor dependency through its fully automated assembly and intelligent testing. In traditional production lines, the assembly of coils, pins, and plugs, as well as resistance testing, often requires multiple workers working collaboratively. However, the ZH-450’s multifunctional assembly and testing capabilities allow these various production steps to be centralized within a single piece of equipment, reducing the complexity of operational handovers and minimizing manual involvement. By adopting the ZH-450, companies can cut labor costs, effectively reduce production expenses, and benefit from the machine's high productivity, which shortens production cycles, enabling companies to fulfill more orders in a shorter time and thus enhancing their competitive edge in the market.

4. Data-Based Model Switching and Flexibility

One of the ZH-450’s remarkable features is its flexible adaptability. The machine is equipped with a model-switching function, enabling quick adaptation to different product specifications by simply changing the data. This feature enhances the machine’s versatility and allows companies to respond swiftly to diverse production needs. For companies with production lines that frequently require model changes, this flexibility increases production line agility and responsiveness, helping companies better meet customer demands and rapidly adjust to market shifts.

Since its founding in 2020, Guangdong Zhenghe Intelligent Technology Co., Ltd. (ZH) has quickly become a leading enterprise in the field of automated electric heating element machinery and intelligent assembly lines in China. Located in Zicheng Industrial Park, Zijin County, Guangdong Province, the company operates a large, modern factory covering 20,000 square meters, with a production area of 15,000 square meters. With advanced automation and intelligent technologies, the company has established a large-scale, highly standardized production environment to provide customers with reliable equipment and services. Not only is ZH well-recognized domestically, but its products have also successfully entered international markets, including Turkey, India, Russia, Brazil, the United States, Mexico, Japan, Thailand, and several other countries.

The R&D team is one of the company’s core competencies, led by experienced and highly skilled experts in the industry, focusing on innovations in automation, smart manufacturing, and robotics. The ZH R&D team closely monitors market needs and technological trends to ensure that each product remains at the forefront of the industry. This commitment to technological innovation and excellence has made ZH products synonymous with high quality and high standards.

Looking ahead, Guangdong Zhenghe Intelligent Technology Co., Ltd. remains committed to ongoing technological upgrades and service optimization to meet the evolving needs of its customers and to drive the future of the industry. ZH aims to work closely with its clients to promote industrial automation advancements and create a smarter, more efficient future.